- Home

- Product

- Road Machinery

- Motor Grader

- SEM

- SEM 915 motor grader

SEM 917 motor grader

August 11, 2022

SEM 510 soil compactor

August 11, 2022SEM 915 motor grader

$78,500.00 $51,500.00

| Brand: Caterpillar/SEM | Type: motor grader |

| Model: SEM 917 | All wheel drive: No |

| Operating weight: 12,200 kgs | Blade width: 3.0m3 |

| Engine power: 110 kw/ 150hp | Warranty: 1 year |

Machine specifications

Improved Engine

- 6.5L Shanghai Diesel engine delivering 150HP

- Best-in-class after treament to ensure the particulate matter and NOX emissions are reduced.

- World-class Diesel Particulate Filter (DPF) is deployed to reduce soot from the exhaust.

- Diesel Exhaust Fluid (DEF) is sprayed in the exhaust by an electronically controlled injector.

- Hydraulically driven engine fan reduces the fuel consumption.

- Caterpillar patented cooling system provides ease of service and longer engine life.

Control System

7 position link bar with optional electric over hydraulic control allows ease of operation from within the cab

- Optimum blade reach capability, quick DCM re-positioning for greater reach for better working on high bank side slope.

- The link bar is essential for extending reach capability when cutting a bank slope or back slope of a ditch.

- Replaceable bushings reduce service time and cost.

Drawbar

- A-frame tubular design drawbar provides maximum strength and durability.

- Replaceable drawbar draft ball (bolted – not welded) for less service time and cost.

- Easy removal of wear shims to adjust drawbar.

Transmission

- Industry leading supplier – Hangzhou Advance Gearbox Group Co., Ltd.

- Specifically designed for motor grader application.

- 6F / 3R electronically controlled hydraulically actuated gears.

- Torque converter ensures steady flow of power to the transmission.

Blade Float

Optional blade float function allows blade to lower without hydraulic pressure for increased versatility.

- Blade float is engaged by pushing the left and right lift cylinder controls all the way forward, past the detent.

- Provides protection for machine and pavement during snow removal and snow plowing.

Front Frame

- Flanged box section design removes welds from high stress areas, improving reliability and durability.

- Continuous top and bottom plate construction provides consistency and strength, improving front frame durability.

- Hydraulic hose routing minimizes exposure to damage and provides quick access for service.

- Maintenance-free bushings improve durability and reduce overall service cost.

SEM Tandem Axle

- Leveraging Caterpillar design and experience on MG tandem axle.

- Mandatory performance testing before delivering to MG assembly line.

- Improved bearing layout and optimized load distribution with 4 planetary gears final drive.

- Less down time and reduced labor and service cost for maintenance and repairing.

- Longer service interval for lubrication oil change.

Hydraulic System

- Proportional Priority Pressure Compensating (PPPC) Valves contain specifically cut spools for motor grader applications, continuously matching of hydraulic flow and pressure to power demands, allowing ease of multi-function control for optimizing working efficiency.

- World-class variable displacement piston pump, efficiently reduces power consumption and hydraulic system heat, improving fuel efficiency.

- Load-sensing hydraulic system provides consistent and precise blade movement, improving finishing performance.

- Inboard lock check valves within PPPC, prevents inadvertent cylinder movement and potential leaks.

- Short throw levers are efficiently spaced, allowing ease of multi-function control.

- Short lever travel (40mm) with low effort reduces operator fatigue, providing exceptional comfort.

Large Cab

- High performance dashboard with 3 levels alarming monition system.

- Cab mounted on the front frame provides exceptional view to blade and front axle even during articulation.

- Large cab with 1.9m height and 30% larger space than most competitors, provides exceptional comfort.

SEM Tandem Axle

- Leveraging Caterpillar design and experience on MG tandem axle.

- Mandatory performance testing before delivering to MG assembly line.

- Improved bearing layout and optimized load distribution with 4 planetary gears final drive.

- Less down time and reduced labor and service cost for maintenance and repairing.

- Longer service interval for lubrication oil change

Cat® Product LinkTM

Cat® Product Link™ will support your business, and accurately convey information of the equipment to relevant personnel in a timely and effective manner for your better equipment management.

Machine data

|

Model |

SM915 |

SM917 |

|

Operating Weight |

||

|

Standard / kg |

12,200 |

13,500 |

|

Engine |

||

|

Engine Manufacturer |

SDEC (ShangHai Diesel) |

SDEC (ShangHai Diesel) |

|

Engine Model |

SC7H150G2B |

SC7H170.1G2B |

|

Rated Power / kW @ RPM |

110 @ 2,200 |

125 @ 2,200 |

|

Max. Torque / kN @ RPM |

570 @ 1,400 |

750 @ 1,400 |

|

Transmission |

||

|

Type |

Converter, Powershift |

Converter, Powershift |

|

Powershift Pressure / MPa |

1.3~1.7 |

1.3~1.7 |

|

Forward / Reverse Gears |

6 Forward / 3 Reverse |

6 Forward / 3 Reverse |

|

Moldboard |

||

|

Blade Width, Standard / mm (inch) |

3,059 (10’) |

3,669 (12’) |

|

Blade Width, Optional / mm (inch) |

3,669 (12’) |

3,972 (13’) |

|

Moldboard Height / mm |

580 (10’ Blade) / 610 (12’ Blade) |

610 |

|

Moldboard Thickness / mm |

20 |

20 |

|

Throat Clearance / mm |

112 |

112 |

|

Float Function |

Optional |

Optional |

|

Moldboard Sideshift, LH / mm |

342 |

647 |

|

Moldboard Sideshift, RH / mm |

463 |

528 |

|

Max. Blade Position Angle |

512 |

512 |

|

Blade Tip, Forward |

663 |

663 |

|

Max. Cutting Depth / mm |

750 |

725 |

|

Service Refill Capacity |

||

|

Fuel Tank / L |

218 |

218 |

|

Engine Oil / L |

17.5 |

17.5 |

|

Transmission / L |

17 |

17 |

|

Hydraulic Oil Tank / L |

55 |

55 |

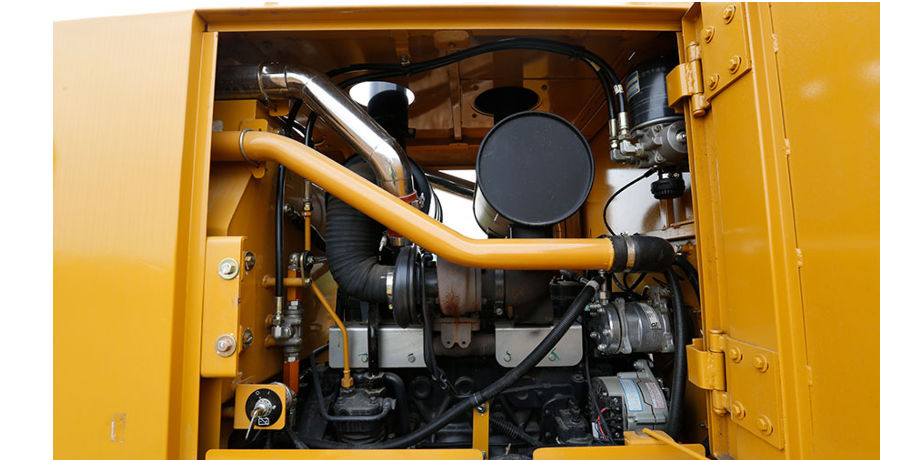

Machine photo

Related products

-

CAT 330 GC crawler excavator

$216,500.00$189,500.00 -

CAT 323GX crawler excavator Tier 4F/ EU Stage V

$175,600.00$157,500.00